Campus News

UC Santa Cruz theater arts costume shop steps up to combat COVID-19

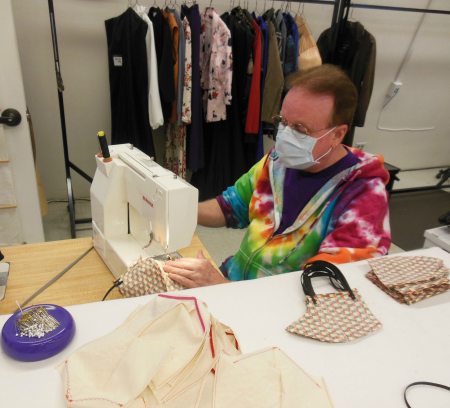

Just a couple of weeks ago, Brent Foland never imagined he’d be building face masks for his fellow UC Santa Cruz employees.

But now, with shelter-in-place requirements being observed, all that has changed. Theaters are dark for the foreseeable future, and face masks have become a key part in keeping us safe from the spread of the coronavirus.

Within the last week, Foland and his assistant Jenna Phillips have been hard at work sewing two varieties of coverings: face masks and neck gaiters. They’re coordinating the project with UCSC’s Environmental Health and Safety department (EH&S), which so far has requested 750 shaped fabric masks and 50 gaiters.Foland first got the idea about making the masks after hearing from his union about other International Alliance of Theatrical Stage Employees (IATSE) around the country building masks for their communities.

“When it became obvious that the proper elastic was unavailable, I felt that we should help out,” said Foland. “We have a very full stock of sewing supplies, so I asked if there was any way Jenna and I could get approval to work in the shop, use the UCSC supplies, and get the masks to UCSC employees in need.”

Since it’s only the two of them working in the shop, Foland and Phillips have made sure to place their sewing machines at least 10 feet apart. All of the material was already in stock in the costume shop, and they’ll purchase additional supplies if necessary.

The shaped, woven fabric masks have two layers of fabric and elastic ear loops or two sets of ties. From cutting to completion, they take 25-30 minutes to make. Each also can have a surgical or dust mask inserted between the two layers for additional protection.

Foland has put his supply of pipe cleaners to clever use by sewing one around the nose area, so the mask can be pinched to fit more snuggly.

Gaiters are worn around the neck and then pulled up over the nose and mouth, and take about 15-20 minutes to make.

Foland and Phillips have an efficient system in place to speed up production where, instead of building complete masks then moving on to the next, they use a step-by-step process. “We are working on each step to make 25 to 40 front layers and the inner lining layers during the first half of the day, then after lunch we sew the two layers together and finish as many as we can before we leave,” said Foland.

EH&S staff pick up finished masks as they’re done and handle the distribution to employees throughout campus.

“The costume shop deserves credit for generously offering to create cloth masks and for their willingness to work on campus during a time of such uncertainty,” said EH&S director Lisa Wisser. “The supply chain for masks of any kind is severely impacted, and the campus is not able to purchase and receive commercially made cloth masks as quickly as the costume shop can make them. We are currently supplying campus staff with disposable masks, but these cloth masks will be much more comfortable, especially for those who need to wear a face covering all day. This is truly a service to our campus community.”

Once the mask needs for employees are met, if there are any overages, they’ll be sent to the University of California medical centers.

“Jenna and I are both very thankful to the numerous people who approved this project and for allowing us to do something positive,” Foland said.